One-Stop Equipment Solutions for Anode Materials

We specialize in designing and delivering full-process equipment solutions for natural graphite — covering spheroidization, purification, coating, carbonization, and final product handling — to meet the growing demand for high-performance anode materials in lithium-ion battery applications.

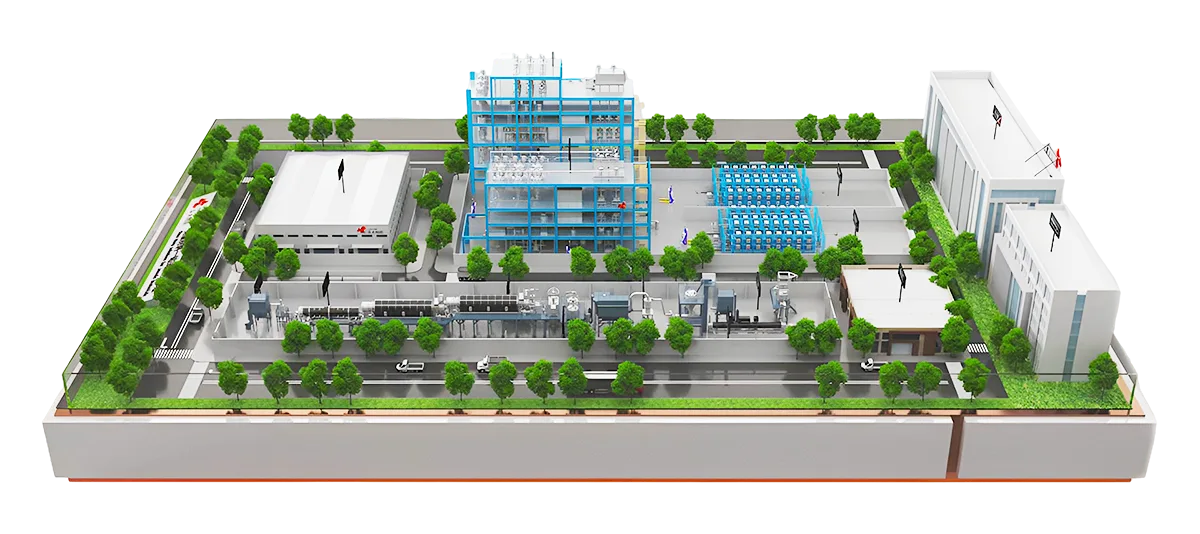

Raw Material Area

Integrated Production

Graphitization Workshop

Final Product Handling System

Storage Area

Office Area

Control Center

Natural Graphite Processing Flow

A step-by-step process from raw graphite to high-performance anode material—engineered for quality, consistency, and battery-grade results.

Raw Material

Natural graphite anodes are made by spheroidizing, purifying, coating, and carbonizing flake graphite. Known for their cost-effectiveness, they are widely used in 3C products and are seeing growing adoption in power batteries as R&D investment increases.

Crushing

The composite crusher crushes natural graphite through high-speed centrifugal collisions and repeated internal friction. A closed-loop system with screening ensures efficient size reduction and consistent particle size.

Flotation

Flotation is a key beneficiation process that separates graphite from impurities based on differences in surface properties. Through the addition of selective reagents and the use of air bubbles, graphite particles attach to bubbles and float to the surface, achieving efficient separation and enhanced purity. This step ensures high carbon content and optimal performance for downstream processing.

Mechanical Spheroidization

The shaping machine and ring roller mill spheroidize flake graphite, enhancing surface area, density, and electrochemical performance. A closed-loop system ensures consistent particle size through repeated collisions and precise screening.

Shaping

Shaping is the process of mechanically refining graphite particles to achieve more uniform dimensions and improve surface smoothness. This step helps optimize particle flow characteristics, prepare them for subsequent processing, and enhance overall material consistency.

Purification

Natural graphite is purified—typically to over 99.95%—by chemical, thermal, or combined methods to remove ash, metals, and other non-carbon impurities, improving electrochemical performance and stability. It is then crushed in a high-speed system where repeated collisions and a closed-loop process ensure precise and consistent particle size.

Coating

Coating is the process of applying a thin, uniform carbon or polymer layer onto the surface of graphite particles. This coating improves electrical conductivity, reduces side reactions with the electrolyte, and enhances the stability of the SEI layer, resulting in better cycle performance and safety of the final anode material.

High Temperature Carbonization

The high-temperature carbonization rotary furnace heats pitch- or resin-coated graphite below 1200 °C to prevent solvent co-intercalation, improving rate capability and cycling stability of the anode material.

Screening, Demagnetization & Packing System

The process begins with screening, where graphite particles are separated according to precise size specifications, ensuring uniformity in electrode performance. This is followed by demagnetization, which removes magnetic impurities that may originate from upstream processes, preventing potential damage to battery performance and safety. The final step is packing, carried out under controlled conditions to protect the graphite from moisture, contamination, and handling damage. By integrating these stages into a single, automated production line, the system achieves high efficiency, stable quality, and reliable delivery of finished graphite anode materials.

Request a Custom Equipment or Solution

Tell us your material, capacity, and process needs — we’ll tailor the right solution for your production line.