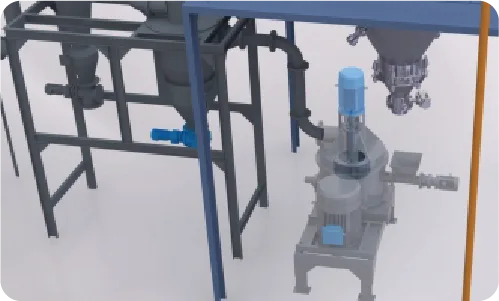

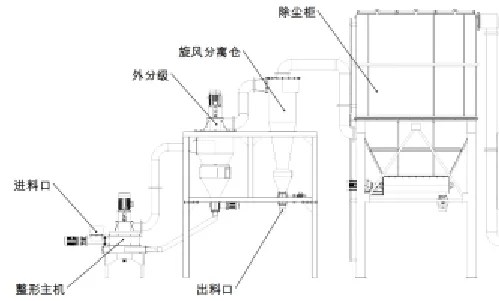

ZDZN TECH has independently developed spheroidizing machines and ring roller mills, specifically designed for the mechanical spheroidization of natural graphite.

In this process, flake graphite is transformed into spherical particles while the powder surface is simultaneously modified. This significantly enhances the electrochemical performance—improving specific surface area and tap density—which leads to higher initial coulombic efficiency, greater reversible charge/discharge capacity, and excellent long-term cycle stability.

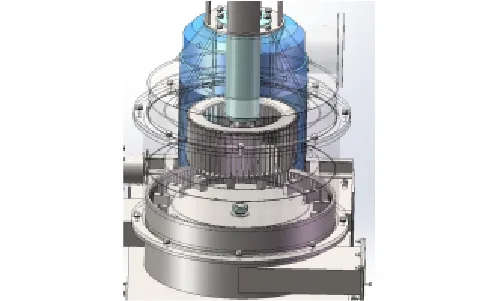

The internal grading adopts a naturally aspirated gas seal design, which can effectively control large particles in the product, make the particle size of the product more concentrated and improve product quality.

Vulnerable parts are made of wear-resistant composite materials, which are more durable than traditional materials in the industry, increasing their service life by more than 20%, reducing downtime and replacement frequency and reduce costs.

Shaping the material through centrifugation, impact, kneading, and other methods, which has a good effect on the depolymerization and dispersion of polymers.

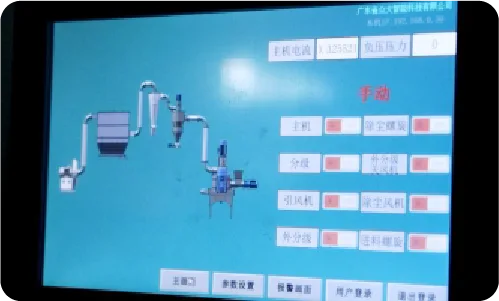

Adopt an intelligent control system, chain automatic control, safe and reliable, simplified operation.

The rotate speed can be adjusted integrating multiple functions with crushing effect and adjustable particle size, effectively controlling the size of product particle size.

Designed with advanced concepts, the system is configured by usage conditions to reduce energy consumption and effectively improve the processing capacity of a single system.

| Model | ZD-ZXJ-100 | ZD-ZXJ-300 |

| Volume | 100L | 300L |

| Main motor power | 37kW | 75kW |

| Graded power | 7.5kW | 11kW |

| Feed granularity | <500μm | <500μm |

| Product granularity | 5-75μm | 5-75μm |

| Capacity | 200-600kg/h | 500-700kg/h |

| Equipment dimension(mm) | 10800x2600x6000 | 10600x2900x6100 |

Tell us your material, capacity, and process needs — we’ll tailor the right solution for your production line.