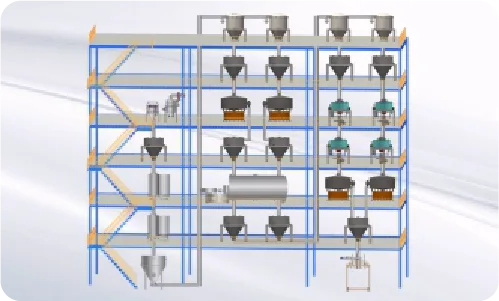

The final product handling system is used for the screening and demagnetization of natural graphite, and includes integrated mixing, screening, demagnetization, and packaging systems. The production line adopts a negative-pressure pneumatic conveying system to minimize dust leakage and material contamination. An intelligent control system manages each stage of the production line, ensuring efficient and stable operation.

During the screening and demagnetization process, materials are separated based on sieve aperture to remove large particles and impurities. Oversized materials are returned for reprocessing, while magnetic substances are eliminated through electric demagnetization.

High-precision equipment is used to mix materials in accurate proportions based on their characteristics, improving the consistency of product performance and minimizing the variation of physical and chemical properties within each batch.

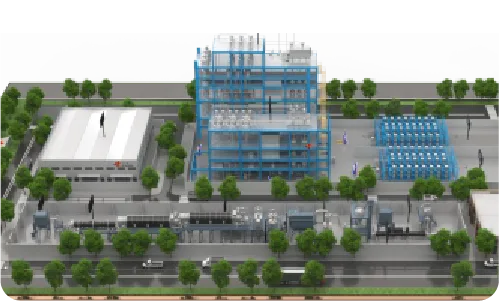

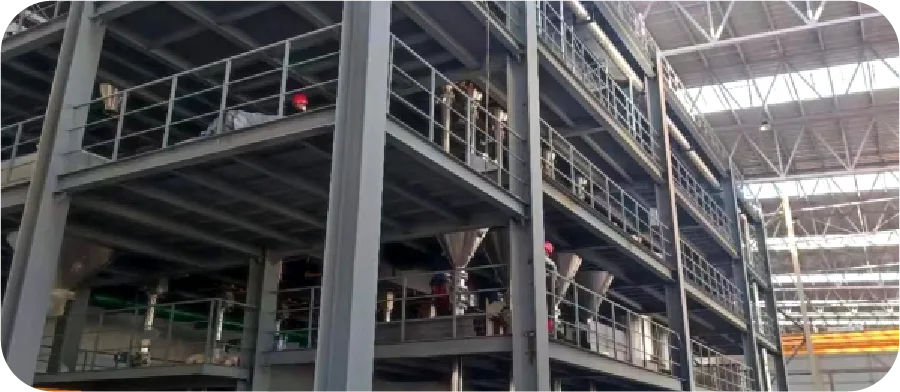

From scheme design, production line equipment manufacturing, project construction, installation, and commissioning, to production support and after-sales service — we provide end-to-end solutions to help customers solve project challenges efficiently.

Intelligent conveying control system software for powder materials enables easier production planning and equipment monitoring, helping to reduce costs and improve operational efficiency.

The system supports integration with intelligent terminal systems, MCS, ERP, and quality management systems to enable production data visualization, real-time data analysis, and other advanced functions.

Adopting a modular and fast-construction approach helps shorten the construction period, reduce costs, and enable rapid project startup.

Tell us your material, capacity, and process needs — we’ll tailor the right solution for your production line.