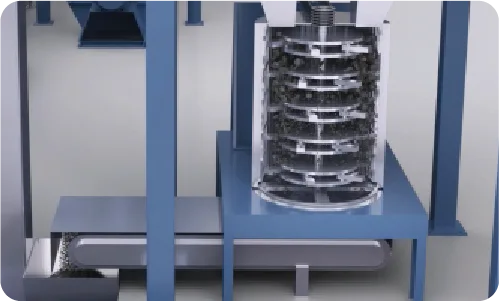

The composite crusher applies to the crushing process of natural graphite.Natural graphite falls vertically from the upper part ofthe machine into ahigh-speed rotating impeller, under the action ofhigh-speed centrifugalforce,it colides and crushes at hizh speed with another pat ofthe materiathat is distributed in a state around the impeller. After the materials collide with each other,they willform vortices between the impeller and theiasing and colide and rub against each other multiple times to crush them., They are discharged directly from the lower part, forming a closed loopwith multiple cycles, and controlled by screening equipment to achieve the particle size of product.

The material will undergo multiple impacts, friction and crushing in the composite crusher to improve the crushing rate.

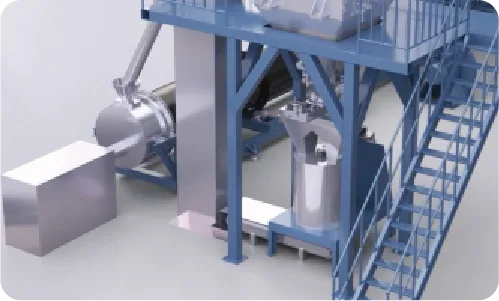

Composite crushers have a wide range of applications and can meet the process requirements for crushing various materials.

The composite crusher is designed using the principle of stone crushing to reduce mechanical wear and production costs.

The composite crusher has fine crushing and coarse grinding functions, meeting the production requirements of various materials.

Less affected by the moisture content of the production materials and the moisture content only reach about 8%.

Reduce dust and impurity pollution during the crushing process and the noise level during operation is below 75 decibels.

| Model | ZD-PSJ-500 | ZD-PSJ-1000 | ZD-PSJ-1500 |

| Volume | 500L | 1000L | 1500L |

| Main motor power | 7.5/4 | 45/4 | 110/4 |

| Feed granularity | <70mm | <120mm | <180mm |

| Product granularity | <3-5 mm | <3-5 mm | <3-5 mm |

| Capacity | 1-5t/h | 20-40t/h | 50-90t/h |

Tell us your material, capacity, and process needs — we’ll tailor the right solution for your production line.