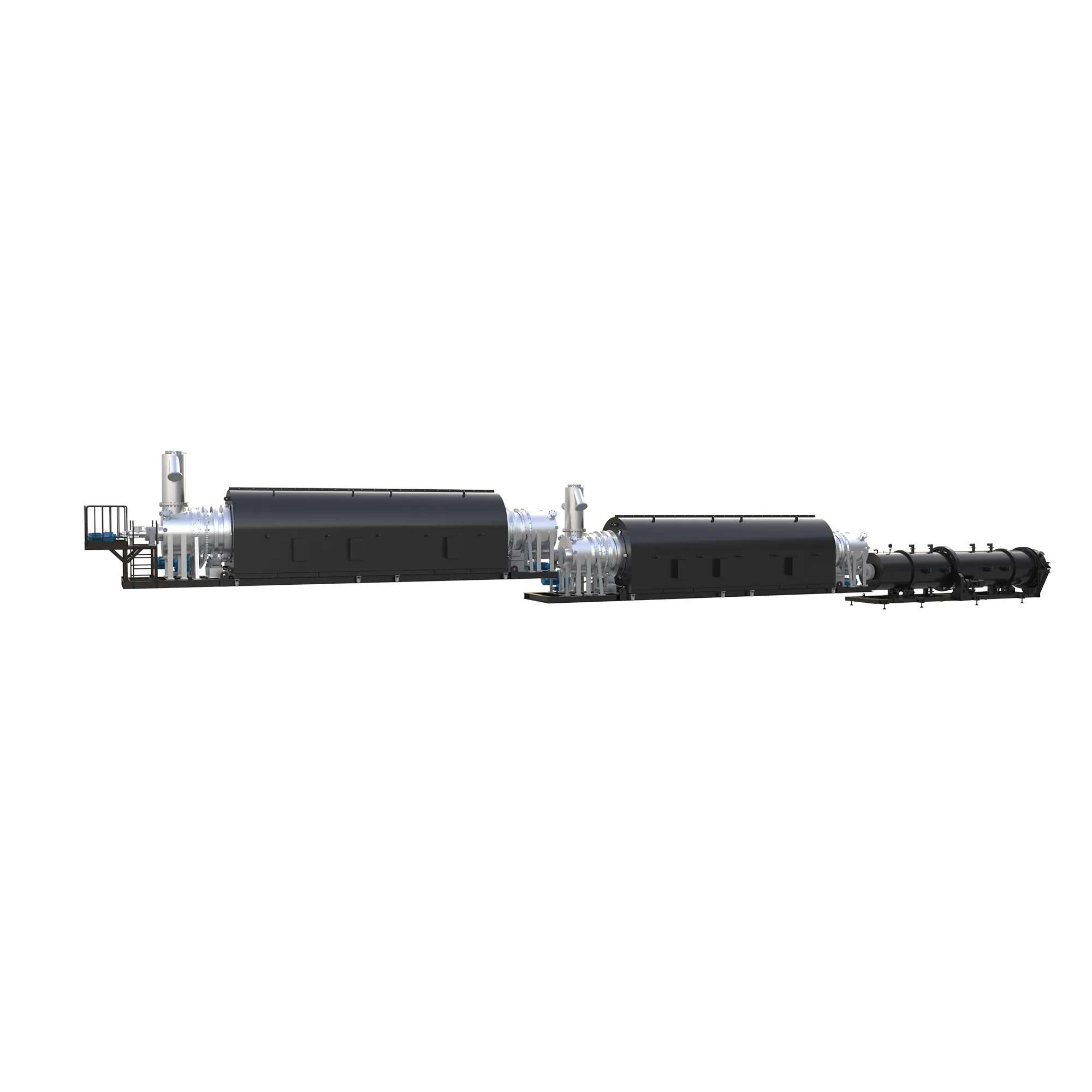

ZDZN TECH has independently developed high-performance ring roller mills and shaping machines, designed for the mechanical spheroidization of natural graphite.

The ring roller mill efficiently grinds flake graphite into fine powder, creating favorable conditions for the subsequent shaping process. During grinding, the powder surface is modified, enhancing specific surface area and tap density. These improvements significantly boost electrochemical performance, leading to higher first coulombic efficiency, greater reversible capacity, and excellent cycle stability in lithium-ion batteries.