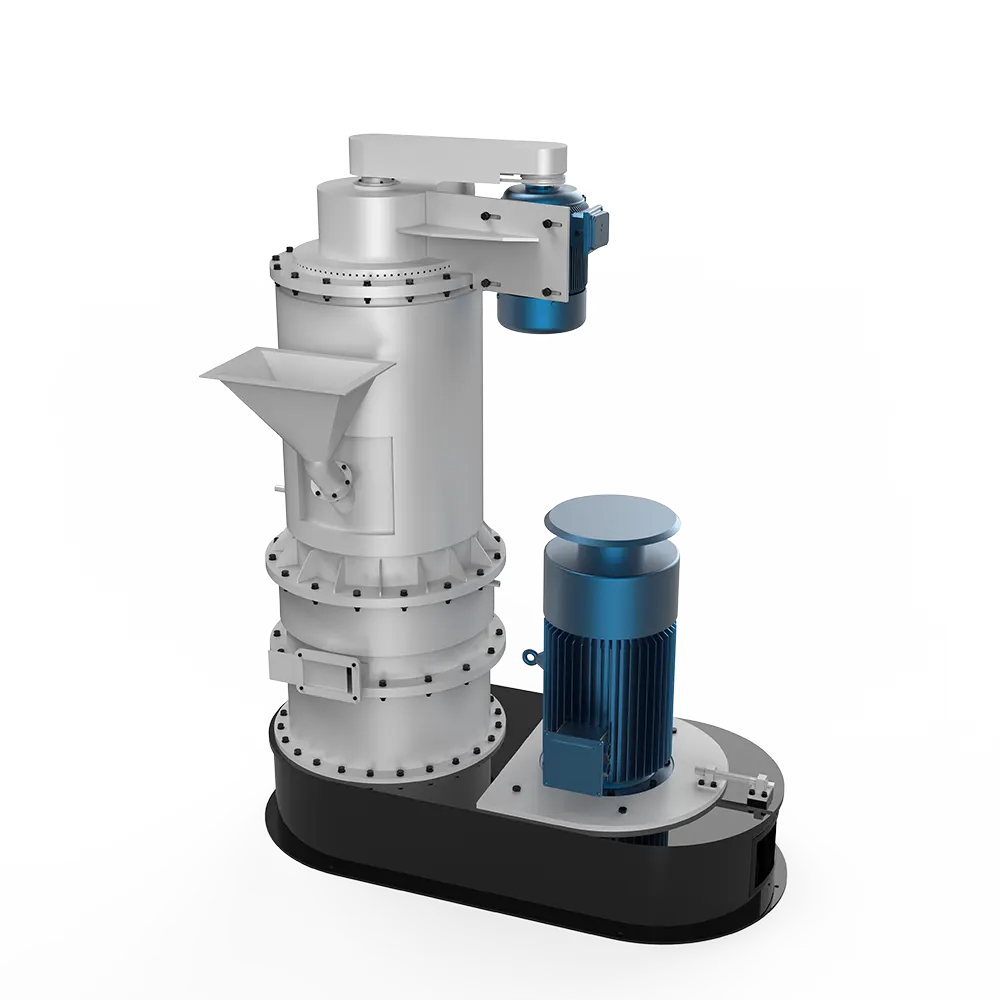

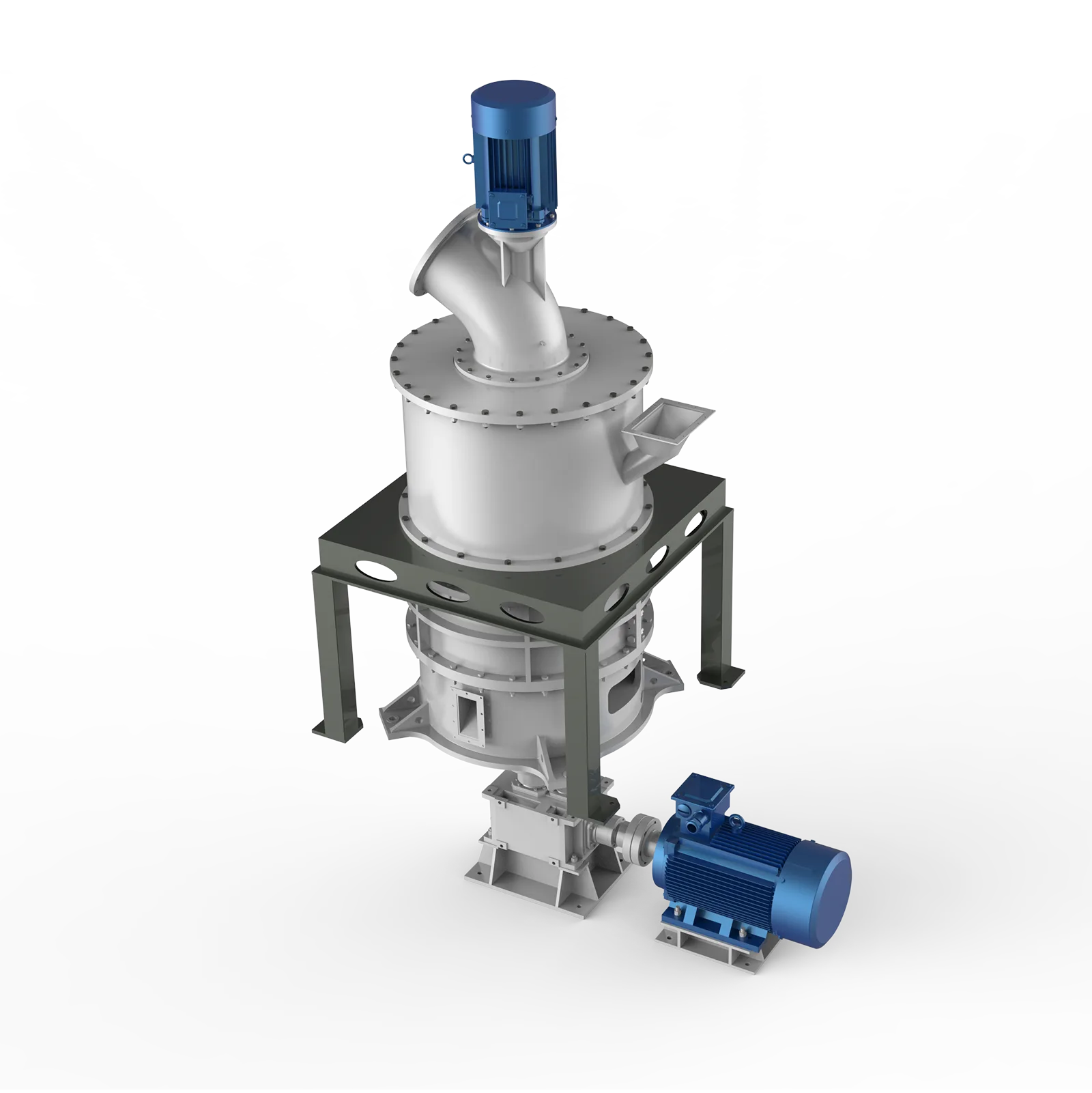

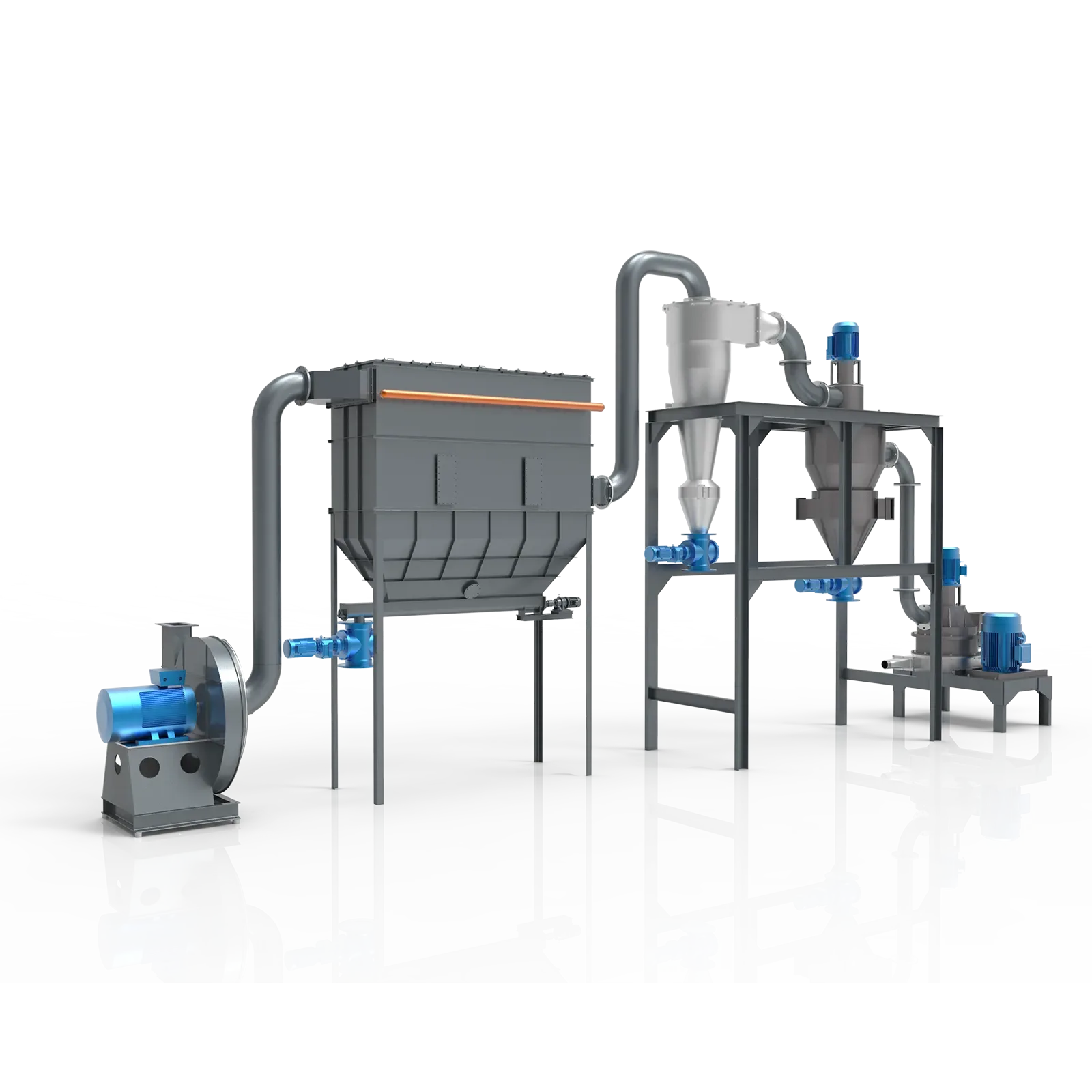

Our mechanical mill is designed specifically for anode material processing and performance improvement. It integrates multiple grinding mechanisms including impact, shear, and compression, handling feed sizes below 10 mm with high efficiency. We have equipped the system with advanced airflow channels and a state-of-the-art classifier, allowing product fineness to be flexibly adjusted within 5–75μm. With reducer-driven transmission and the material-layer grinding principle, our machine operates with low energy consumption and real-time classification to avoid over-grinding. The final powders are uniform in particle distribution and further stabilized through secondary classification via the classifier wheel and cyclone separator. Operating under micro-negative pressure, the system is safe, environmentally friendly, and easy to maintain. In addition, our intelligent control system allows automatic adjustment and smooth operation. With our targeted main machine design and optimized system control, we help you achieve precise particle size distribution and higher yields.