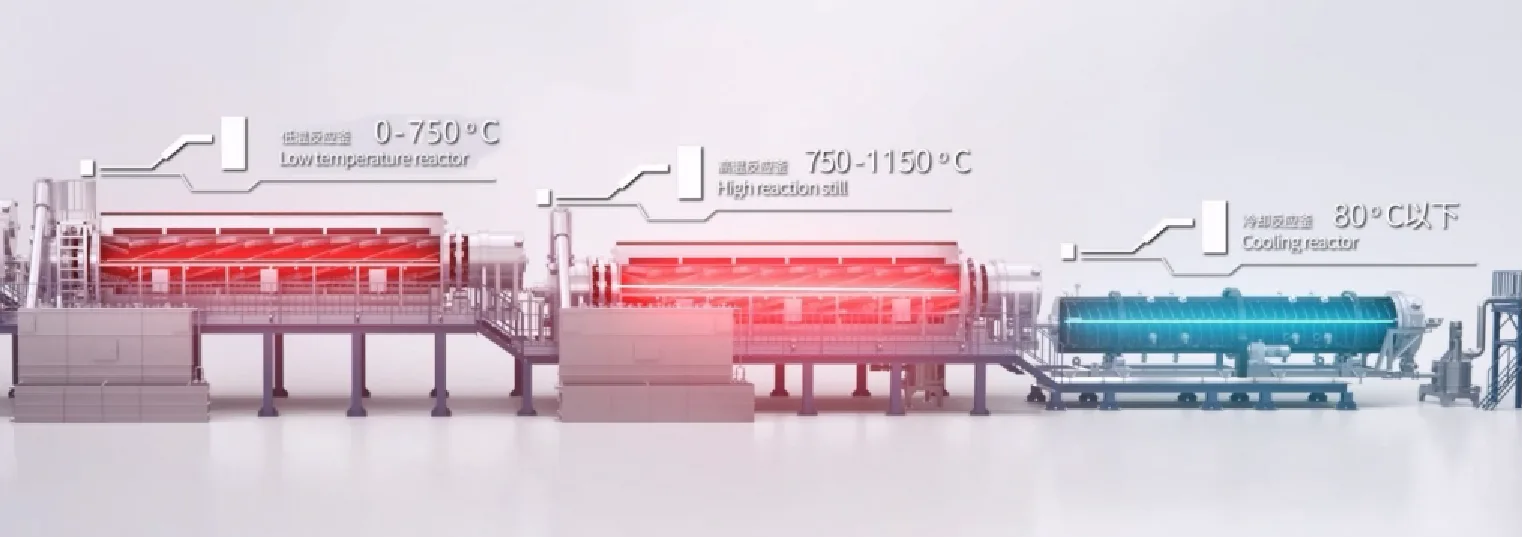

The high-temperature carbonization rotary furnace is used for the high-temperature carbonization process of natural graphite. Inside the furnace, graphite is coated with a layer of asphalt or resin-based polymer material at temperatures below 1200 °C. This coating helps prevent the co-embedding of small organic molecules, thereby further improving the rate performance and cycling stability of the anode material.

Equipment Dimensions: 47.9×3.8×5.7m

Low Magnetic Impurity Content.

Specific Surface Area & Raman Value: Customized according to customer requirements and produced in compliance with qualified standards.

Investment: 50%–60% of that required for a rail kiln

Land Occupation: 70% of that of a roller kiln

Energy Consumption: 40%–50% lower than a roller kiln

Adopting an inner-lining non-metallic cylinder, this design pioneers a solution to the problem of inconsistent thermal expansion between non-metallic and metallic materials.

The high-temperature carbonization process does not require a crucible, reducing production costs by up to 40%.

The furnace uses a specially designed non-metallic material structure to ensure that the magnetic substance content remains below 1 ppm. The atmospheric conditions inside the furnace can be flexibly adjusted as needed.

Using curve temperature control technology, the system precisely regulates the furnace temperature. With an operating temperature of 1150 °C, it ensures that the carbonization process remains within the optimal temperature range.

High-temperature carbonization removes most non-carbon elements and impurities from the material, significantly increasing its overall purity.

The closed-pore structure formed after high-temperature carbonization provides abundant lithium storage sites, enhancing both the lithium storage capacity and cycling stability of the material.

Carbonized materials exhibit higher specific surface area, enhanced electrical conductivity, and reduced irreversible capacity loss, thereby improving the energy density and cycle life of batteries.

| Parameter | Value |

| Capacity | 15 ton per day |

| Operating temperature | ~1150 ℃ |

| Discharge temperature | ≤80 ℃ |

| Power | 1840 kW |

| Temperature zones | 15 |

| Furnace atmosphere | Nitrogen / Ammonia |

| Atmosphere consumption | 150 m³/h |

| Cooling water consumption | 70-90 m³/h |

Copyright © 2025 Guangdong Zhongda Intelligent Technology Co., Ltd. All Rights Reserved