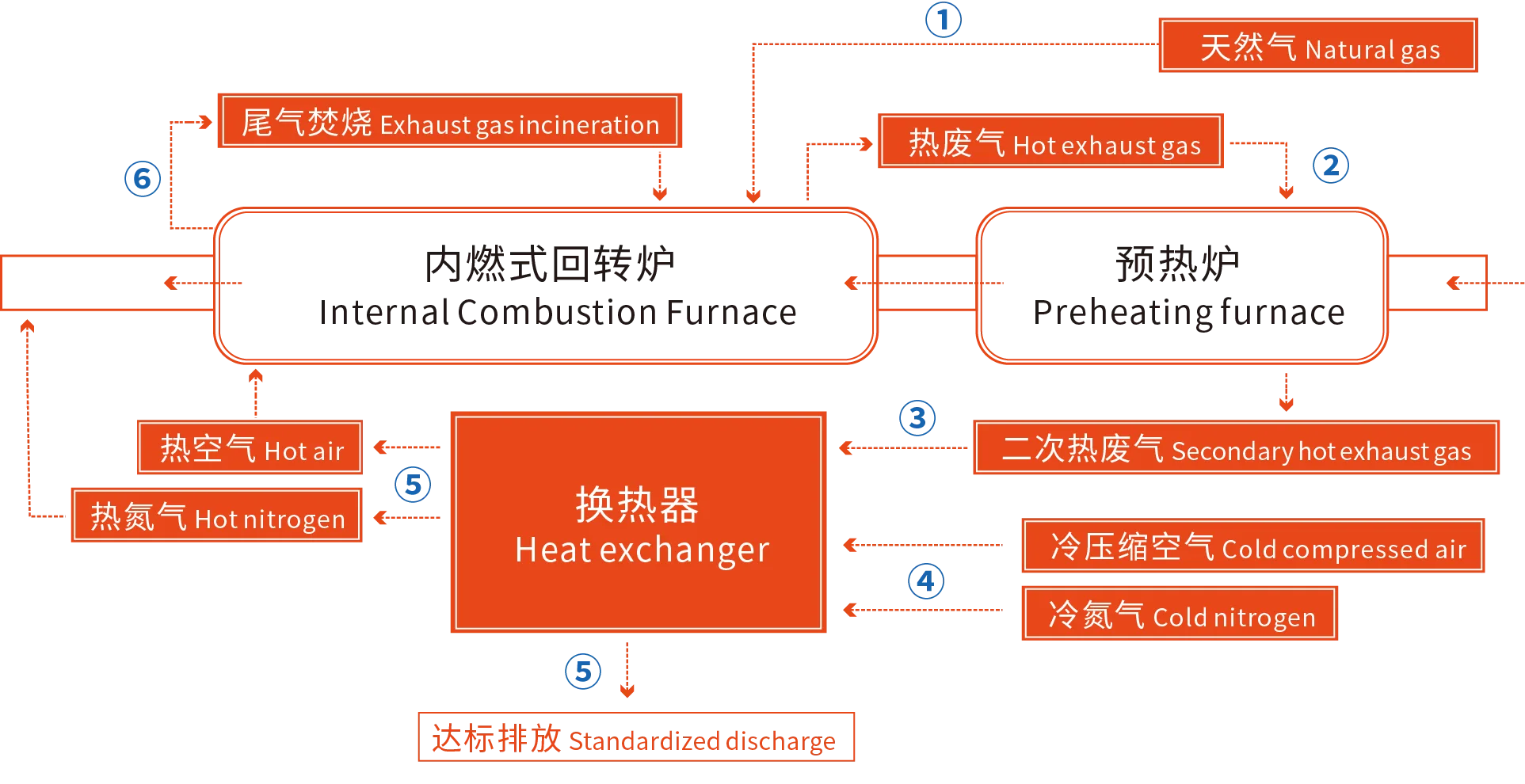

The internal combustion coated granulation rotary furnace is used for the surface modification of natural graphite. It adopts natural gas heating and preheating recovery technology to reduce energy consumption and operational costs. During the heating process, a layer of amorphous carbon is coated onto the surface of natural graphite, effectively filling defects in the graphite layers. This enhances the electrochemical performance of graphite electrode materials and makes the equipment well-suited for continuous, large-scale production.

Equipment Dimensions: 56×4.2×5.5m

Independently researching and designing high-temperature purifiers, recycling and reusing finished materials extracted from exhaust pipes, improving the yield and quality of material products (applicable to granular and powder types), and effectively treating tar blockages to ensure that tar does not condense.

Natural gas 20 Nm ³/T, fully incinerated and recycled exhaust gas, processed and recovered exhaust gas heat energy through the recycling system, reused for furnace heating or front-end drying, reducing operating costs and exhaust gas treatment costs and meeting environmental protection needs.

The cylinder is made of special customized materials that are resistant to high temperatures, with high corrosion resistance. Reduce the content of magnetic materials.

Adopt composite structure designs such as packing, graphite ring, and airtight seal, and the shaft seal part is completely sealed with mechanical seal components.

The gas heating efficiency is high, with a large calorific value, which can quickly reach the required temperature, save heating time, and quickly reach production conditions.

Equipped with monitors provide real-time feedback on equipment status, effectively controlling the separation, purification, and treatment of exhaust gas, acidic gases, etc.

| Parameter | Value |

| Capacity | 15 ton per day |

| Operating temperature | ~1050 ℃ |

| Discharge temperature | ≤80 ℃ |

| Power | 120 kW |

| Temperature zones | 14 |

| Heating natural gas consumption | 120 Nm³/h |

| Furnace atmosphere | Nitrogen |

| Atmosphere consumption | 100-200 m³/h |

| Cooling water consumption | 70-90 m³/h |

Copyright © 2025 Guangdong Zhongda Intelligent Technology Co., Ltd. All Rights Reserved