Customer Service

We’re committed to providing responsive, reliable, and long-term support to every customer. From pre-sales consultation to after-sales assistance, our team ensures a smooth experience through technical guidance, timely maintenance, and lifelong service.

Raw Material Testing

We conduct comprehensive testing to evaluate the physical, chemical, and performance characteristics of your incoming materials. These results form the foundation for process design, ensuring compatibility and optimal efficiency in the following production stages.

Pilot Line

Our pilot line provides a controlled, scalable environment to validate your process before full-scale production. Through small-batch trials, we optimize parameters, identify potential issues, and ensure the process is reliable and efficient. This crucial step bridges lab testing and industrial-scale operations, reducing risk and accelerating implementation.

EPC Services

Our EPC (Engineering, Procurement, and Construction) services offer comprehensive turnkey solutions for your projects. From detailed engineering design and equipment procurement to on-site construction and commissioning, we manage every phase to ensure timely, cost-effective, and high-quality project delivery. With our integrated approach, you can focus on your core business while we handle the complexities of project execution.

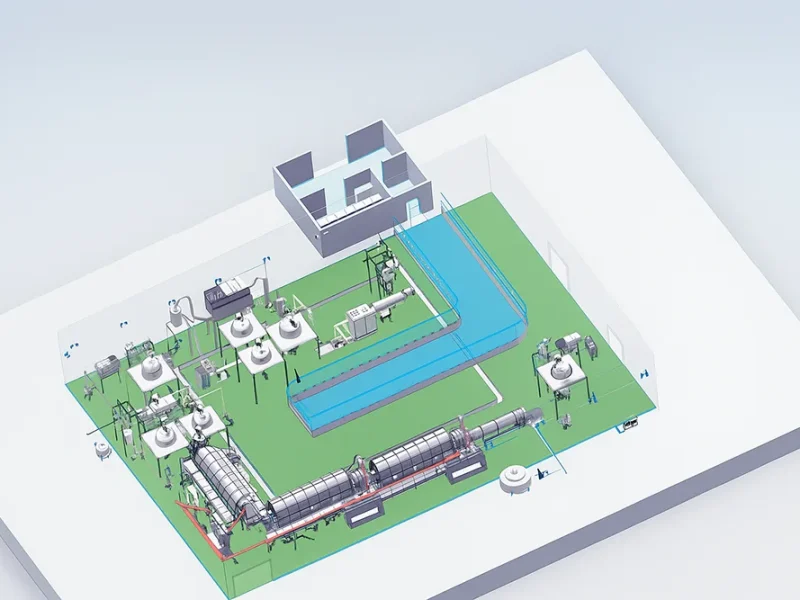

Plant Layout Design

We provide customized plant layout designs that take into account your facility’s dimensions, space limitations, and workflow needs. Each design is optimized for smooth material flow, efficient equipment arrangement, and safe operations, while leaving room for future expansion. By combining practicality with scalability, we ensure every layout supports reliable, cost-effective, and sustainable production.

Equipment Manufacturing

Unlike traditional EPC contractors, we are also the manufacturer of the core production equipment. This allows us to control the entire supply chain—from R&D, machining, and assembly to quality testing. Equipment is tailored to the customer’s process specifications, ensuring seamless integration and reliable long-term operation. With strict quality assurance and precision manufacturing, we provide a full set of advanced production lines for natural graphite and other anode materials.

Engineering & Construction

We manage the full engineering and construction phase, including civil works, utilities, equipment installation, and on-site commissioning. Our team ensures strict adherence to design specifications, project timelines, and international standards. After installation, we provide training, trial runs, and performance validation, so the production line can quickly achieve stable output. By taking full responsibility for the entire process, we deliver projects that are ready for immediate operation.

Request a Custom Equipment or Solution

Tell us your material, capacity, and process needs — we’ll tailor the right solution for your production line.